Alversdorfer Weg 1

Schöningen

Industrial washing machines

and plant engineering

High-performance System using the Most Modern Technology

German English Home References Contact Imprint How to reach us GDP Data Protection

Continuous Washing Machines

1. Washing Machines for Metal Parts

2. Washing Machine for Uncoated, Splined Shafts

3. Washing Machines for Jointed Components

4. Washing Machines for Wheel Hub Parts De-flashing & Polishing

5. Washing Machines for Wheel Hub Parts after Clearing

6. Washing Machine for Jointed Housing of Mechanical Processing

7. Washing Machine for Jointed Shaft Pipes

8. Washing Machine for Jointed Shaft Pipes before Enameling

9. Washing Machine for Metal Parts

10. Washing Machine for Truck Frame Rails

11. Washing Machine for Carriers

Booth Washing Machines

1. Booth Washing Machine for Metal Parts

2. Booth Washing Machine for Bearing Partse

3. Booth Washing Machine for Metal Parts in Baskets

4. Booth Washing Machine for Small Parts in Baskets

5. Booth Washing Machine for Pivot Bearings

Immersion Washing Machines

1. Immersion Washing Machine for Metal Parts

Tank Washing Machines

1. Tank Washing Machine for Stainless Steel Containers with Circular Chain

2. Tank Washing Machine for Stainless Steel Containers

3. Tank Washing Machine for Stainless Steel Containers with Circular Chain in Explosive Area

Washing and De-flashing Systems

1. Booth Washing & De-flashing Machine for AGW Modules

2. Cycle Continuous Washing & De-flashing Machine for Oil Pump Housings

1. Washing Machines for Metal Parts

2. Washing Machine for Uncoated, Splined Shafts

3. Washing Machines for Jointed Components

4. Washing Machines for Wheel Hub Parts De-flashing & Polishing

5. Washing Machines for Wheel Hub Parts after Clearing

6. Washing Machine for Jointed Housing of Mechanical Processing

7. Washing Machine for Jointed Shaft Pipes

8. Washing Machine for Jointed Shaft Pipes before Enameling

9. Washing Machine for Metal Parts

10. Washing Machine for Truck Frame Rails

11. Washing Machine for Carriers

Booth Washing Machines

1. Booth Washing Machine for Metal Parts

2. Booth Washing Machine for Bearing Partse

3. Booth Washing Machine for Metal Parts in Baskets

4. Booth Washing Machine for Small Parts in Baskets

5. Booth Washing Machine for Pivot Bearings

Immersion Washing Machines

1. Immersion Washing Machine for Metal Parts

Tank Washing Machines

1. Tank Washing Machine for Stainless Steel Containers with Circular Chain

2. Tank Washing Machine for Stainless Steel Containers

3. Tank Washing Machine for Stainless Steel Containers with Circular Chain in Explosive Area

Washing and De-flashing Systems

1. Booth Washing & De-flashing Machine for AGW Modules

2. Cycle Continuous Washing & De-flashing Machine for Oil Pump Housings

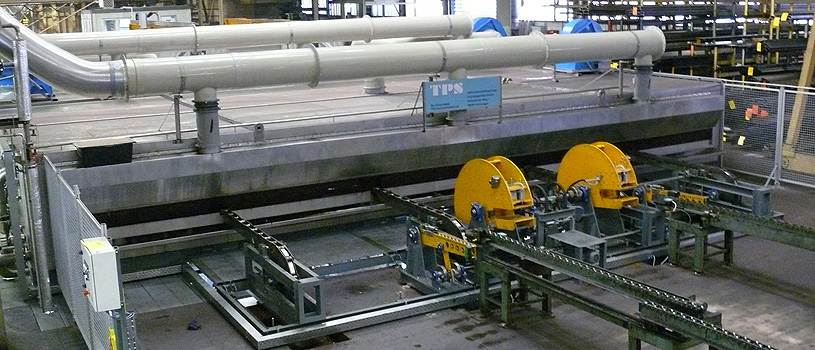

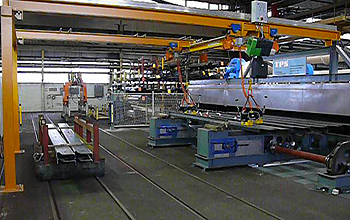

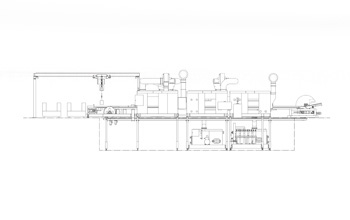

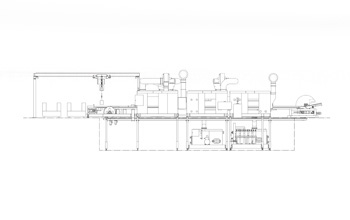

Three-zone/cycle Continuous Washing Machine for Truck Frame Rails

Specification:

Object to be cleaned:

Contamination:

Component size:

Component weight:

Throughput:

Movement:

Cleaning agents:

Cleaning cycles:

Washing processes:

Special equipment:

Heating:

Installation area:

Long frame rails for truck chasses

Drawing oil, shavings & dirt from movement

L = from 4,000 up to 12,000 mm

W = from 200 up to 400 mm

H = from 40 up to 100 mm

max. 400 kg / rail

42 sec. / long frame rail

Automated using turning tables, chain conveyors and loading by cranes with lifting magnets

Water-based cleaning agent

Spray wash, spray rinse & circulated air dry

Sieve filtration, full flow filtration & degreasing

Drain unit, residual oil removal system

Heating technology

L x W x H of 23,000 x 14,000 x 3,300 mm on two levels

Object to be cleaned:

Contamination:

Component size:

Component weight:

Throughput:

Movement:

Cleaning agents:

Cleaning cycles:

Washing processes:

Special equipment:

Heating:

Installation area:

Long frame rails for truck chasses

Drawing oil, shavings & dirt from movement

L = from 4,000 up to 12,000 mm

W = from 200 up to 400 mm

H = from 40 up to 100 mm

max. 400 kg / rail

42 sec. / long frame rail

Automated using turning tables, chain conveyors and loading by cranes with lifting magnets

Water-based cleaning agent

Spray wash, spray rinse & circulated air dry

Sieve filtration, full flow filtration & degreasing

Drain unit, residual oil removal system

Heating technology

L x W x H of 23,000 x 14,000 x 3,300 mm on two levels

TPS - Industriewaschmaschinen- und Anlagenbau GmbH - Alversdorfer Weg 1 - 38364 Schöningen - Germany - Telefon: 00495352/96820-10 - Fax: 00495352/96820-29

Copyright 1998 - 2024 ALL RIGHTS RESERVED